Just like the human race, medical science also keeps evolving to maintain pace with evolution. A stop to any such beneficial change can hinder not just the mechanism of the world, but can also present as an aggravator to the degeneration of survival. Given the fact that the medical space is vast and varied; there are numerous branches that it is divided into. And, orthopedics is an important part of it.

This field of medical science is of great significance due to its focus on treating illnesses and injuries of the musculoskeletal system (bones, joints, ligaments, tendons, cartilage). Thus, experts are constantly on their toes to produce upgraded and compatible materials to manufacture orthopedic implants and instruments that are not just metal but much more.

But, were you ever curious to know where this concept of metal implants and instruments has come into orthopedics? How has it evolved from a metal pin or wire to high-quality medically biocompatible materials today? Well, we certainly are!

So, in this blog, we shall dig into the history to find out the 3 I’s - inception, invention and intention behind such an exceptional evolution in orthopedics that has made such a difference in people’s lives.

Evolution of Orthopedic Implants

1. Metal Implants – The first choice

One can certainly not decide upon the first time an implant was used, but as per an article, a French manuscript in 1775 discussed a fracture being stabilized using iron wire. And, it was after that, the first surgical fracture repair was done by the end of the eighteenth century.

Using a cerclage wire was one of the most commonly proposed methods to fix fractures in those times. However, it is not practically possible to internally fix the broken bones using these wires.

Joseph Lister introduced antiseptic techniques that eventually made surgeries safer and possible. And, then by 1858, Carl Hansmann performed the first internal fixation using plates and screws, which did mark the beginning of orthopedic implants ethically.

2. Stainless steel implants

Somewhere in the early 1900s, Sir William Arbuthnot Lane and some other orthopedic experts created a metal plate made up of stainless steel. It is an alloy composed of iron, nickel, chromium, and some parts of carbon. A few years later, William Sherman of Pittsburgh modified Lane’s method using vanadium iron rather than steel for its excellent strength and rigidity.

Further, a new evolution occurred and molybdenum was found. It was added to stainless steel as a component and was majorly preferred due to its resistance to biological fluids. However, at this time, the materials used were not biologically acceptable to the body and its tissues. Thus, the prosthetics were fitted in surgically and removed once their purpose was achieved.

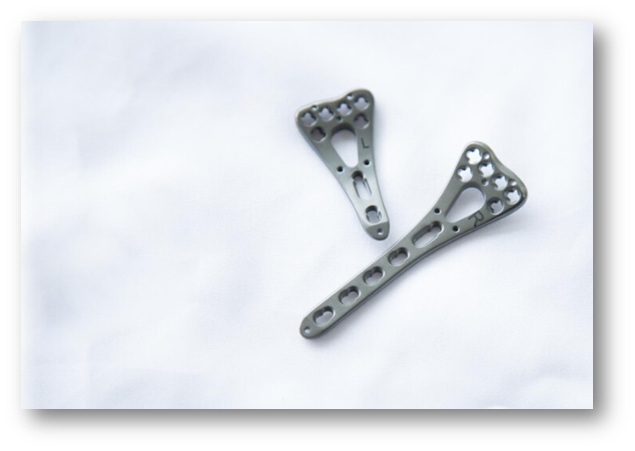

3. Titanium and Cobalt-Chromium implants

As time passed, development in technology became rapid and it resulted in the introduction of titanium and cobalt-chromium alloys. They were used due to less corrosion and higher biocompatibility. The treatment of degenerative joint diseases became easier due to the introduction of joint replacement procedures using these metal implants. The titanium-based alloys were used less for cemented hip replacement prostheses due to a lower elasticity than surgical stainless steel.

4. Ceramic Implants

By the end of the 1900s, imaging techniques, manufacturing technologies, and computer-assisted designing (CAD) had arrived. And, so had the ceramic implants also! It was a British physicist Ron Garvie who created the first zirconia-based material in the year 1975.

These innovative ceramic implants were used for orthopedic and dental procedures. From a medical perspective, we can definitely say that they were as effective as any other implant material used during that century. It was found to be very biocompatible and ideal for dental implants, which was then followed by its usage in making hip replacement prostheses.

5. Polymeric Implants

The polymeric material is used widely in the field of orthopedics and trauma. In contrast to ceramics and some metal implants, polymers have an inadequate elastic modulus close to the cortical bone. When using these biomedical polymers for orthopedic surgeries, their chemical and biological features were also satisfactory. They were resistant to constant wear and tear caused by the movement of the implants and also prevented the accumulation of debris in the joint.

6. Coated Implants

The cement-less coated joint replacement implants have proven to be an exemplary advanced invention in orthopedics. These porous coated implants are based on the concept of biological adaptation which results in bone ingrowth. Historically, this idea existed way before, but its long performance was a concern.

After trial and error of decades conducted by several medical scientists, orthopedics was rewarded with various porous coated implants that gave good results. The significance of porous-coated prosthetic devices in orthopedics is that they provide efficient replacements for the treatment of specific patient populations.

7. 3D - Printed Implants

The arrival of tissue engineering led to the application of 3D printing techniques in the manufacturing of biomedical orthopedic implants. Properly designed 3D-printed implants have better biocompatibility and efficiency besides removing the stress-buffering effect.

Medical imaging methods like MRI, X-ray, and ultrasonic scanning can be paired with 3D printing to manufacture implants unique to each patient. These implants adjust properly to the original anatomical structure. The advancement of 3D printing in medical implants can be limited due to the scarcity of appropriate raw materials and the absence of regulatory advice.

8. Biodegradable Implants

As the name implies, these implants are created using 100% biocompatible materials that dissolve and are absorbed in the body over time. From joint replacements to fracture repair, bio-absorbable implants are utilized for a variety of medical treatments because they promote regeneration of tissue and healing from within while providing stability as well as support for a short time.

Conclusion

The main objective of discussing the complete process of evolution in orthopedic implants and instruments was to showcase the intersection between material features, tissue engineering, regenerative procedures, and patient comfort.

All these implants are manufactured with the intent of excellent surgical results that lead to patient wellness in the long term. And, this is an incessant process, as science always comes with a scope for improvement than the last time.